Introduction

The milking time of individual cows has a major affect on output in milking sheds. The rate of milk extraction depends on the average vacuum applied to the teat-end during the milking phase of pulsation (b-phase). This vacuum level depends on the degree of vacuum drop due to the components between the vacuum pump and the teat-end. Most modern milking machines have large-bore milk pipelines in which the vacuum losses are low. The main vacuum losses occur from frictional losses and hydrostatic effects in the connecting system from the teat to the milk pipeline during milk flow. Under practical milking conditions these losses are difficult to measure, as the flow through individual teats is not known. O’ Callaghan (2001) developed a flow simulator to record vacuum losses in commercial milking plants. With this simulator, insertion of artificial teats into the liners simulated the flow conditions from the teat and rate of water flow was controlled. Flow simulation tests (O’Callaghan, 1997, 2003; O’Callaghan and Gleeson, 1999, 2001 ) on a range of milking systems have shown that the applied vacuum during milk flow can vary by up to 30% depending on the configuration of the milking system.. There is limited data on the effect of applying different levels of milking vacuum on milking characteristics and particularly milking time.

Materials and Methods

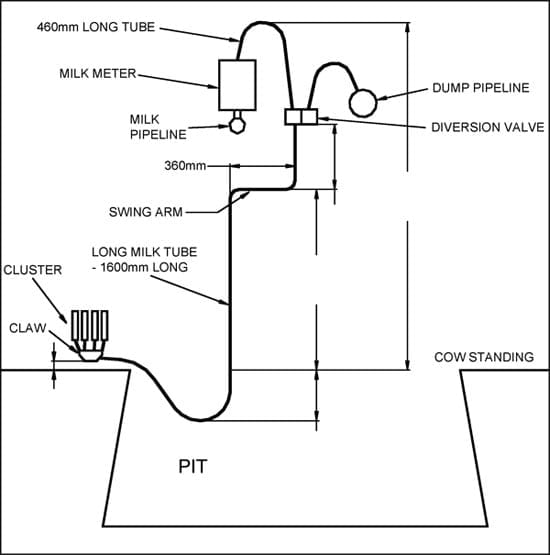

Four configurations of a milking unit shown in Figure 1 were calibrated with a portable flow simulator (O’Callaghan and Gleeson, 2001) at a water flowrate of 4 l /min to give vacuum levels during the b-phase of pulsation of 35, 38, 40 and 42 kPa at the apex of an artificial teat during simulated milking. Simultaneous (4×1) and alternate (2×2) pulsation patterns and two bores of long milk tubes (LMT) were used to establish these differences in teat end vacuum (Table 1). The vacuum traces recorded with the flow simulator for the four treatments are shown in Figures 2 to 5 at a flow of 4 l/min.

Friesian cows (N=56) were milked in a 14 unit side-by-side parlour in a Latin Square design experiment to establish the effect of altering the teat-end vacuum levels on milking characteristics. The system vacuum level for the mid-level milking plant was set at 49 kPa. A pulsation rate of 60 Hz was used for the four treatments and the “a”, “b”, “c” and “d” values of the pulsation chamber waveform were 12.0%, 56.2%, 11.3% and 20.5% respectively. One cluster type fitted with wide bore tapered liners, a 150 ml claw and a cluster weight of 3.16 kgs was used for the four treatments. Milk yields and milk flow profiles were recorded automatically with Dairymaster Weigh-all electronic milk meters. Clusters were removed automatically at a milk flow-rate of 0.2 kg/min. Milking time was computed as the time interval from cluster application to when the milk flow reached 0.2 kgs/min. Pre-milking preparation consisted of washing teats with warm running water and drying with individual paper towels.

Figure 1. X-section of milking unit for milking tests

Table 1. Details of milking treatments

| Treatment | Pulsation Pattern | Bore of LMT (mm) | Vacuum at 4 l/min (kPa) |

| T1 | 4×1 | 16.0 | 42 |

| T2 | 4×1 | 13.5 | 40 |

| T3 | 2×2 | 16.0 | 38 |

| T4 | 2×2 | 13.5 | 35 |

Figure 2. Vacuum traces of pulsation chamber vacuum, claw vacuum and teat end vacuum with a 16mm bore LMT and simultaneous (4×1) pulsation

Figure 3. Vacuum traces of pulsation chamber vacuum, claw vacuum and teat end vacuum with a 13.5 mm bore LMT and simultaneous (4×1) pulsation.

Figure 4. Vacuum traces of pulsation chamber vacuum, claw vacuum and teat end vacuum with a 16 mm bore LMT and alternate (2×2) pulsation.

Figure 5. Vacuum traces of pulsation chamber vacuum, claw vacuum and teat end vacuum with a 13.5 mm bore LMT and alternate (2×2) pulsation.

Results

The milking characteristics obtained with the four configurations of milking units are presented in Table 2. Altering the vacuum level at the teat-end or reducing vacuum loss in a milking system had no significant effect on milk yield. When the LMT bore was increased from 13.5 mm to 16 mm milking vacuum was increased by 2kPa with 4×1 pulsation during simulation tests. In the milking trial this increase in milking vacuum reduced the milking time by 40 seconds per cow, and increased both the average and peak milk flowrate (P<0.0001). With alternate pulsation the teat end vacuum increased from 35 kPa to 38 kPa when the LMT was increased from 13.5 mm bore to 16 mm, this reduced the milking time by 36 seconds per cow. The milking characteristics were similar when simultaneous pulsation and a 13.5 mm LMT were compared to alternate pulsation and 16 mm LMT.

Table 2. Milking characteristics recorded with four milking units calibrated with a flow simulator at 4l/min.

| Treatment number | T1 | T2 | T3 | T4 | ||

| Vacuum at 4 l/min | 42 | 40 | 38 | 35 | s.e.d | Sig. |

| Milk yield per milking(kg) | 20.1 | 20.2 | 19.9 | 19.7 | 0.4 | ns |

| Milking time (sec) | 427 | 467 | 463 | 499 | 8.6 | *** |

| Average flow (kg/min) | 2.9 | 2.6 | 2.6 | 2.5 | 0.05 | ** |

| Peak flow (kg/min) | 4.9 | 4.6 | 4.5 | 4.2 | 0.08 | *** |

Discussion

The present ISO standard (ISO 6690, 1996) for milking machines specify that flow capacity of milking units should be proportional to the amplitude of vacuum fluctuation. This standard is presently been revised and international experts involved in the revision agree that vacuum level at the teat-end during the b-phase of pulsation is a more important measurement than the level of vacuum fluctuation. While the amplitude of vacuum fluctuation at the teat-end recorded during flow simulation for wide-bore tapered liners is high with simultaneous pulsation the vacuum loss during the b-phase or milking phase is low and fast milking was achieved in the present trial with simultaneous pulsation and 16mm bore LMT. Worstorff and Hollweck (1995) showed that the presence of large vacuum losses reduced milk yield and increased milking time. In the present trial increasing the vacuum loss did not affect milk yield.

There is a practical benefit in increasing the bore of the LMT with either simultaneous or alternate pulsation with wide bore tapered liners in terms of less time required for the milking process. Most milking plants in Ireland have a milk tube bore in the range 13.5-14 mm. The results indicate that new milking plants and conversions should have 16mm bore LMT and 16mm bore entries in the milk pipeline. During the flow simulation tests the vacuum variations were similar in the claw and at the apex of the artificial teat. Thus measurements of vacuum taken in the claw during actual milking represent teat end conditions.